I-MBB Low Profile Peench Scale enesisindo esincanyana se-Sensor Ediature Beng Beam Load Cell

Izici

1. Ama-Capacities (kg): 20 kuye ku-100

2. Ukuklanywa kwephrofayili ephansi

I-3. Isakhiwo esihlangene, kulula ukuyifaka

4. Ukunemba okuphezulu okuphelele, ukuqina okuphezulu

5

6. I-degree yokuvikelwa ingafinyelela ku-IP66

7. Shell Ukufaka

Izinja

1. Isikali esiphansi se-Deck

2. Imishini yokupakisha, izikali zeBelt

3. I-Dosing feeder, umshini wokugcwalisa, isilinganiso se-hopper

4. Izithako ezinesisindo sokulawula kumakhemikhali, ezemithi, ukudla kanye nezinye izimboni

Ukufanisa

I-MBB iseli lomthwalo wamandla aphansi, izikali eziphansi zedeski nesikali sethangi. I-alloy esebenza ngensimbi esetshenziswayo ihlinzeka ngokumelana okusesigabeni okungcono kakhulu kuma-creep and shock imithwalo uma iqhathaniswa namaseli ajwayelekile asetshenziswa ama-aluminium. I-Special Searning Material isetshenziselwa ukubekwa uphawu okugcwele, izinga lokuvikela lifinyelela ku-IP66, futhi linezimpawu ezinhle kakhulu zokuvimbela umswakama nomumo wamanzi kusuka ekungeneni. Amandla aqala kusuka ku-20kg kuya ku-100kg, futhi angenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende.

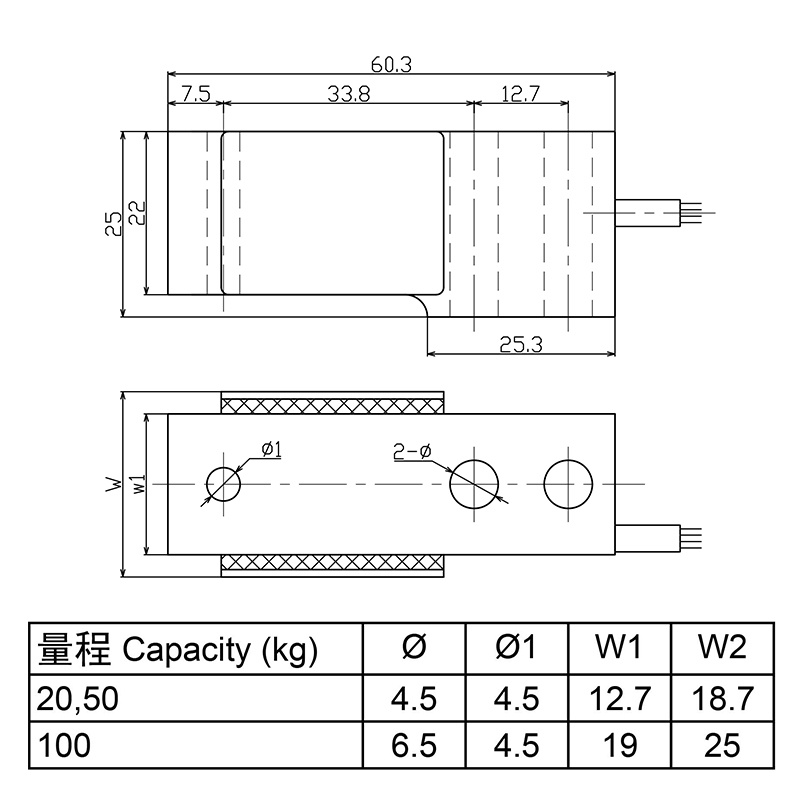

Ubukhulu

Amapharamitha

| Ukucaciswa: | ||

| Umthwalo olinganiselwe | kg | I-20,50,100 |

| Ukukhishwa okulinganiselwe | MV / V | I-3.0 |

| Ukulingana okungu-zero | % Ro | ± 1 |

| Iphutha eliphelele | % Ro | ± 0.03 |

| Okungeyona i-LineARYity | % Ro | ± 0.03 |

| Hysteresis | % Ro | ± 0.03 |

| -Phindaphiwe | % Ro | ± 0.02 |

| Phezulu ngemuva kwemizuzu engama-30 | % Ro | ± 0.03 |

| Isinxephezelo se-temp.range | ℃ | -10 ~ + 40 |

| I-Temp.range | ℃ | -20 ~ + 70 |

| Temp.effect / 10 ℃ ekuphumeni | % Ro / 10 ℃ | ± 0.02 |

| Temp.effect / 10 ℃ ku-zero | % Ro / 10 ℃ | ± 0.02 |

| Kunconywe amandla okuvuselela | I-VDC | 5-12 |

| I-VOLTAGE ephezulu yokuvuselelwa | I-VDC | 5 |

| Ukufakwa kokuvikelwa | Ω | 380 ± 10 |

| Ukukhishwa kwe-Implance | Ω | I-350 ± 5 |

| Ukumelana nokufakelwa | Mp3 Ngqo | = 5000 (50VDC) |

| Ukulayishwa ngokweqile okuphephile | % RC | 50 |

| Ukulayisha ngokweqile | % RC | 300 |

| Into uqobo lwayo | Insimbi ye-alloy | |

| Degree of ukuvikelwa | IP66 | |

| Ubude bentambo | m | 2 |

| Ikhodi ye-wiring | Ex: | Okubomvu: + Mnyama: - |

| Sig: | Luhlaza: + mhlophe: - | |