I-FLS FORKLLIFT SYSTEDE LICH

Ukuchaza izincazelo

Uhlelo lwe-Forklift elekthronikhi elinesisindo lunesisindo sempahla futhi lubonisa imiphumela ngenkathi i-Forklift ithwala izinto zakho ze-Pallet ezinesisindo ukuthuthukisa umkhiqizo kanye nokuvuselelwa kwemali. Isikali sethu se-Forklift sihlangabezana nezindinganiso zokuthembela, ukuphepha kanye nokunemba kwezicelo ezisetshenziswa kanzima.

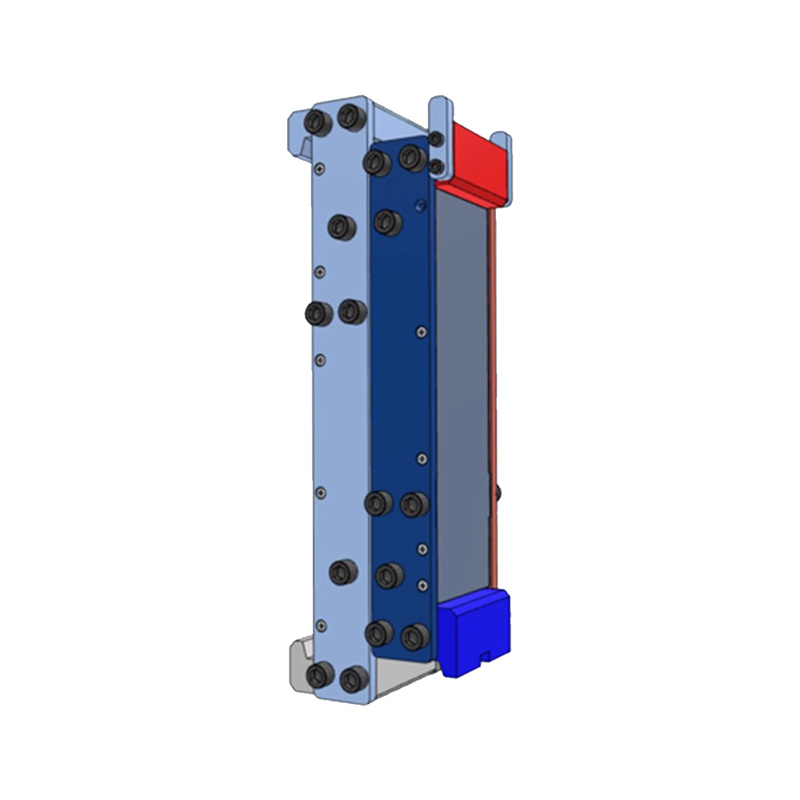

Lo mkhiqizo okhethekile onesisindo onesakhiwo esiqinile nokuguquguquka okuhle kwemvelo. Isakhiwo esikhulu se-LTS sifaka: Izinhlobo ezimbili zohlobo lwebhokisi olunesisindo ngakwesobunxele nakwesokudla, ezisetshenziselwa ukukhweza imfoloko, inzwa enesisindo, i-jungction ibhokisi, ithuluzi lokubonisa kanye nezinye izingxenye. Idizayini ebanjiwe kanye nokumiswa kwelungelo lobunikazi ukumiswa kwesilinganiso semodyuli kuqinisekisa imiphumela enobunzima emibandela ezindabeni ezinzima kakhulu, ezinobunzima nezimo ezinzima, ngaphandle kwezindleko noma inkinga yokuphindisela kabusha noma ukuhlupheka kokuphinda kwenziwe kabusha.

Isici esivelele kakhulu salolu hlelo olunesisindo ukuthi aludingi ukuguqulwa okukhethekile kwesakhiwo seForklift yasekuqaleni noma isakhiwo kanye nokumiswa kwendlela yemfoloko nokuphakamisa imodyuli enesisindo esilinganayo kanye ne-lifting module phakathi kwemfoloko nelifti. Imodyuli yokulinganisa okufanele yengezwa ihlanganiswe kudivayisi ephakamisa i-forklift nge-hook, futhi imfoloko ilengiswe kumodyuli yokulinganisa ukuze uqaphele umsebenzi onesisindo. Iwindi lokuhlekisa kakhulu kanye ne-terminal ecwecwe elicwebezelayo kwenza kube lula ukuthi opharetha we-forklift abone izithonjana zomthwalo wemfashini wokuphakamisa nokugwema izingozi.

Izici

Uhlelo lwe-Forklift elekthronikhi elinesisindo lunesisindo sempahla futhi lubonisa imiphumela ngenkathi i-Forklift ithwala izinto zakho ze-Pallet ezinesisindo ukuthuthukisa umkhiqizo kanye nokuvuselelwa kwemali. Isikali sethu se-Forklift sihlangabezana nezindinganiso zokuthembela, ukuphepha kanye nokunemba kwezicelo ezisetshenziswa kanzima.

Lo mkhiqizo okhethekile onesisindo onesakhiwo esiqinile nokuguquguquka okuhle kwemvelo. Isakhiwo esikhulu se-LTS sifaka: Izinhlobo ezimbili zohlobo lwebhokisi olunesisindo ngakwesobunxele nakwesokudla, ezisetshenziselwa ukukhweza imfoloko, inzwa enesisindo, i-jungction ibhokisi, ithuluzi lokubonisa kanye nezinye izingxenye. Idizayini ebanjiwe kanye nokumiswa kwelungelo lobunikazi ukumiswa kwesilinganiso semodyuli kuqinisekisa imiphumela enobunzima emibandela ezindabeni ezinzima kakhulu, ezinobunzima nezimo ezinzima, ngaphandle kwezindleko noma inkinga yokuphindisela kabusha noma ukuhlupheka kokuphinda kwenziwe kabusha.

Isici esivelele kakhulu salolu hlelo olunesisindo ukuthi aludingi ukuguqulwa okukhethekile kwesakhiwo seForklift yasekuqaleni noma isakhiwo kanye nokumiswa kwendlela yemfoloko nokuphakamisa imodyuli enesisindo esilinganayo kanye ne-lifting module phakathi kwemfoloko nelifti. Imodyuli yokulinganisa okufanele yengezwa ihlanganiswe kudivayisi ephakamisa i-forklift nge-hook, futhi imfoloko ilengiswe kumodyuli yokulinganisa ukuze uqaphele umsebenzi onesisindo. Iwindi lokuhlekisa kakhulu kanye ne-terminal ecwecwe elicwebezelayo kwenza kube lula ukuthi opharetha we-forklift abone izithonjana zomthwalo wemfashini wokuphakamisa nokugwema izingozi.

Amayunithi ayisisekelo wohlelo lwe-forklift elekthronikhi

1. Uhlobo lwebhokisi lokulinganisa isilinganiso semodyuli yokulinganisa (kufaka phakathi inzwa nebhokisi le-junction)

2. Ukuboniswa kwesisindo

Isimo Sokusebenza Ngemuva kokufaka imodyuli yokumiswa yokumiswa