WR Dynamic Belt Scale For Iron And Steel Chemical Industry

Features

• Excellent accuracy and repeatability

• Unique parallelogram load cell design

• Fast response to material loads

• Capable of detecting fast running belt speeds

• Rugged construction

Description

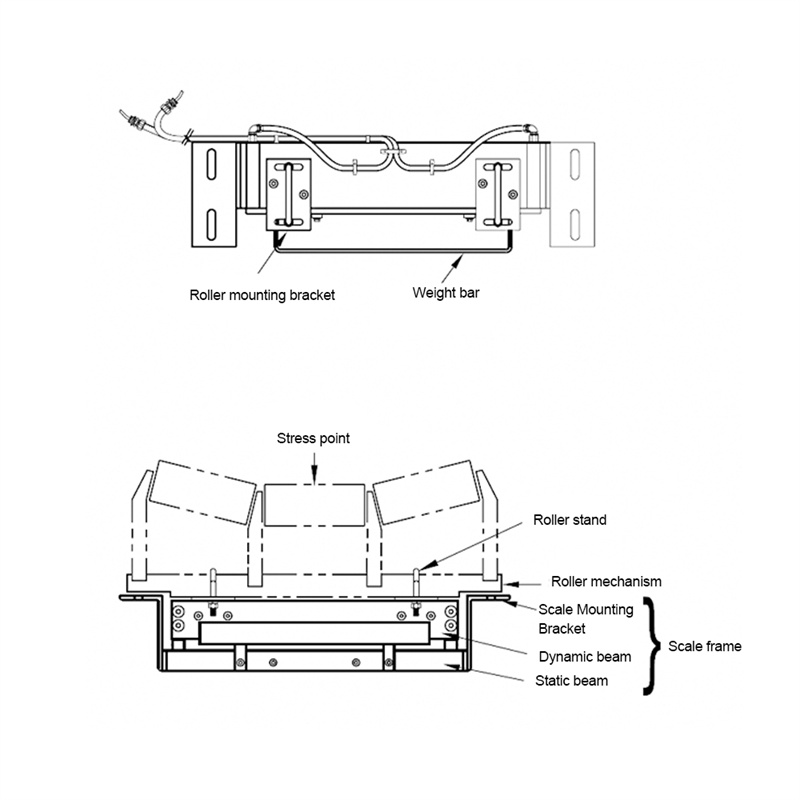

WR belt scales are heavy duty, high precision full bridge single roller metering belt scales for process and loading.

Belt scales do not include rollers.

Applications

WR belt scale can provide continuous online measurement for various materials in different industries. WR belt scales are widely used in various harsh environments in mines, quarries, energy, steel, food processing and chemical industries, fully proving the excellent quality of WR belt scales. The WR belt scale is suitable for different materials such as sand, flour, coal or sugar.

The WR belt scale uses the parallelogram load cell developed by our company, which responds quickly to the vertical force and ensures the sensor's rapid response to the material load. This enables WR belt scales to achieve high accuracy and repeatability even with uneven material and fast belt movements. It can provide instantaneous flow, cumulative quantity, belt load, and belt speed display. The speed sensor is used to measure the conveyor belt speed signal and send it to the integrator.

The WR belt scale is easy to install, remove the existing set of rollers of the belt conveyor, install it on the belt scale, and fix the belt scale on the belt conveyor with four bolts. Because there are no moving parts, the WR Belt Scale is low maintenance requiring only periodic calibration.

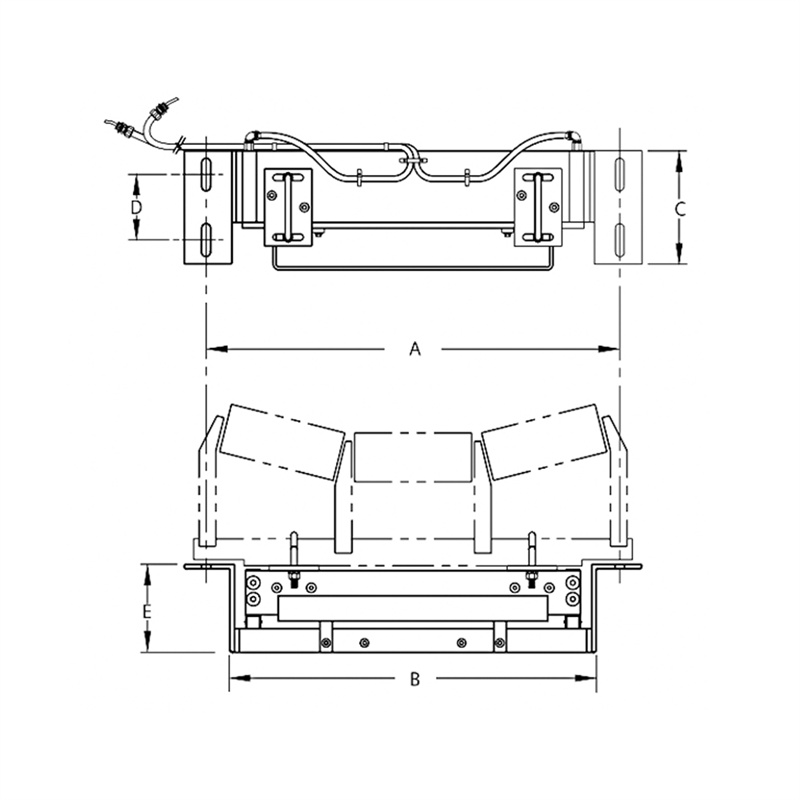

Dimensions

|

Belt width |

Scale frame installation width A |

B |

C |

D |

E |

Weight (approx.) |

|

457mm |

686mm |

591mm |

241mm |

140mm |

178mm |

37kg |

|

508mm |

737mm |

641mm |

241mm |

140mm |

178mm |

39kg |

|

610mm |

838mm |

743mm |

241mm |

140mm |

178mm |

41kg |

|

762mm |

991mm |

895mm |

241mm |

140mm |

178mm |

45kg |

|

914mm |

1143mm |

1048mm |

241mm |

140mm |

178mm |

49kg |

|

1067mm |

1295mm |

1200mm |

241mm |

140mm |

178mm |

53kg |

|

1219mm |

1448mm |

1353mm |

241mm |

140mm |

178mm |

57kg |

|

1375mm |

1600mm |

1505mm |

305mm |

203mm |

178mm |

79kg |

|

1524mm |

1753mm |

1657mm |

305mm |

203mm |

178mm |

88kg |

|

1676mm |

1905mm |

1810mm |

305mm |

203mm |

203mm |

104kg |

|

1829mm |

2057mm |

1962mm |

305mm |

203mm |

203mm |

112kg |

Specifications

| Operation method | Strain gauge load cells measure the load on a belt conveyor |

| Metrology principle | Stone sorting system |

| Typical application | Trade and delivery |

| Measurement accuracy | +0.5 % of totalizer, turndown 5:1

Cumulative soil 0.25%, turndown ratio 5:1 +0.125% of totalizer, turndown ratio 4:1 |

| Material temperature | 40~75°C |

| Belt design | 500 - 2000 mm |

| Belt width | Refer to dimension drawing |

| Belt speed | up to 5 m/s |

| Flow | 12000 t/h (at maximum belt speed) |

| Conveyor Inclined | Fixed inclination relative to horizontal +20°

Reaching ±30° will result in reduced accuracy(3) |

| Roller | From 0°~ 35° |

| Groove angle | to 45, reduces accuracy(3) |

| Roller diameter | 50 - 180 mm |

| Roller spacing | 0.5~1.5m |

| Load cell material | Stainless Steel |

| Degree of protection | IP65 |

| Excitation voltage | Normal 10VDC, maximum 15VDC |

| Output | 2+0.002 mV/V |

| Nonlinearity and Hysteresis | 0.02% of rated output |

| Repeatability | 0.01% of rated output |

| Rated range | 25, 100, 150, 250, 300, 500, 600, 800kg |

| Maximum range | Safe, 150% of rated capacity

Limit, 300 % of rated capacity |

| Overload | -40-75°C |

| Temperature | Compensation -18-65°C |

| Cable | <150 m18 AWG(0.75mm²) 6-conductor shielded cable

>150 m~300 m;18~22 AWG (0.75 ~ 0.34 mm²) 8-core shielded cable |

1. Accuracy description: On the installed belt measuring system approved by the manufacturer, the cumulative amount measured by the belt scale is compared with the weight of the tested material, and the error is less than the above standard. The amount of test material must be within the design range, and the flow rate must be stable. The minimum amount of material must be the higher of three full revolutions of the belt or 10 minutes.

2. If the belt speed is higher than the value described in the manual, please consult the engineer.

3. Engineer inspection is required.

Installations