In today’s fast-paced industrial environment, efficiency and accuracy are paramount. On-board weighing systems are changing how loaders and trucks work. They give real-time weight data. This helps optimize loading, boosts safety, and increases productivity. These systems are now essential for businesses that want to stay competitive.

What are On-Board Weighing Systems?

Manufacturers add on-board weighing systems by installing scales on loaders and trucks. These systems give operators quick weight readings while loading and transporting. So, there’s no need to stop at stationary scales. This saves time and resources. It also streamlines operations and reduces the risk of overload.

8200 On-board weighing load cell for coal trucks

Benefits of On-Board Weighing Systems:

- Increased Efficiency: On-board systems give real-time weight data. This helps operators load vehicles to the maximum legal limit without exceeding it. This helps avoid under-loading, which wastes transport space. It also prevents over-loading, which can lead to fines, safety risks, and vehicle damage. The result is a more efficient use of resources and reduced operating costs.

- Improved Safety: Overloaded vehicles are a significant safety hazard. They are more likely to have accidents. Weak brakes, poor maneuverability, and extra stress on tires and suspension cause this. On-board weighing systems stop overloading. This keeps drivers and road users safe.

- Lower Maintenance Costs: Overloading can wear out vehicle parts faster. This leads to expensive repairs and downtime. On-board weighing systems stop overloading. This helps vehicles last longer and cuts maintenance costs.

607A 10T On board weighing load cell for cement flow control

- Better Accuracy and Reliability: New on-board weighing systems use smart sensors and algorithms. This helps them give very accurate and dependable weight readings. This removes the guesswork in estimating loads. It ensures compliance with regulations and boosts profitability.

- Data Logging and Reporting: Many on-board weighing systems can log data. This helps businesses track weight over time. Use this info to analyze loading patterns. Find areas to improve and create compliance reports.

- Versatility: On-board weighing systems work with many types of loaders and trucks. This includes wheel loaders, articulated dump trucks, excavators, and tractor-trailers. You can tailor them to fit the unique needs of various applications and industries.

- Cost Savings: The initial cost of an on-board weighing system might seem high. However, it can lead to significant savings over time. Spending less on fuel and cutting maintenance costs helps you save money. To avoid fines and increase productivity, you can quickly recover your investment.

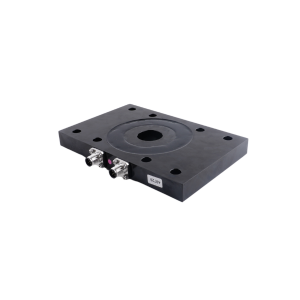

607A 30t Double Ended Shear Beam Load Cell

Key Components of an On-Board Weighing System:

The core of an on-board weighing system is the load cell. Load cells are transducers that convert force (weight) into an electrical signal. A display unit processes the signals. This unit gives the operator a clear and accurate weight reading. Other key components may include:

- Sensors: These sensors detect the load on the vehicle’s axles or suspension.

- Indicators/Displays: These units display the weight information to the operator. They often include features such as overload alarms and data logging capabilities.

- Wiring and Cables: These components connect the various parts of the system.

- This hardware secures the system to the vehicle with a strong hold.

Load Cell Manufacturers: Key Players in the Industry

The load cells you choose impact the quality and performance of an on-board weighing system. Reliable manufacturers make top-notch load cells for many industrial applications, including on-board weighing. Here are some considerations when choosing a load cell manufacturer:

- Accuracy: Look for manufacturers that offer load cells with high accuracy ratings. The load cell’s accuracy affects the whole weighing system’s precision.

- Durability: On-board weighing systems are often subjected to harsh environments. Pick load cells that can handle shock, vibration, temperature changes, and tough conditions.

- Choose a manufacturer known for making reliable load cells. They should need little maintenance.

- Calibration and Certification: Ensure load cells are properly calibrated and certified to meet industry standards.

- Customer Support: Choose a manufacturer that offers excellent customer support and technical assistance.

- Technology: Advanced load cell makers will likely offer digital output load cells. These provide better connectivity and accuracy.

Conclusion:

On-board weighing systems are changing how loaders and trucks work. They offer big benefits like improved efficiency, safety, and cost savings. Investing in a quality on-board weighing system helps businesses. It optimizes loading procedures, prevents overloading, lowers maintenance costs, and boosts productivity. Picking the right load cell manufacturer is key. It helps guarantee system accuracy and reliability. As technology advances, on-board weighing systems will get smarter. They will also fit into larger fleet management solutions. This will increase their value and make them crucial for businesses in loading and transport.

Post time: Mar-28-2025