Chemical companies rely on storage and metering tanks for material storage and production but face two main challenges: material metering and production process control. Based on experience, using weighing sensors or modules effectively resolves these issues, ensuring accurate measurements and improved process management.

Tank weighing systems are widely used across industries. In the chemical industry, they support explosion-proof reactor weighing systems; in the feed industry, batching systems; in the oil industry, blending weighing systems; and in the food industry, reactor weighing systems. They are also applied in glass industry batching and similar setups like material towers, hoppers, tanks, reactors, and mixing tanks.

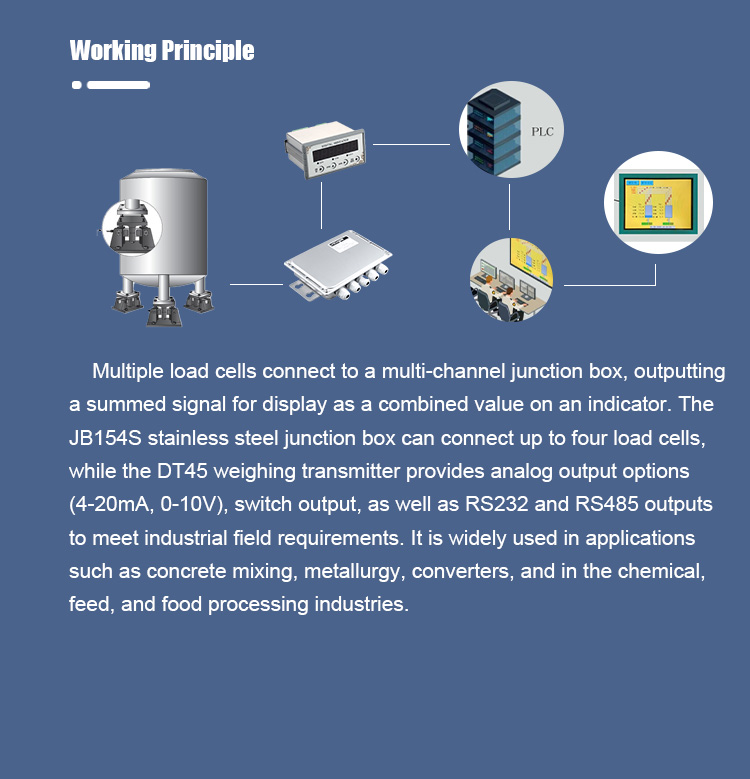

Functional overview of tank weighing system:

The weighing module can be easily installed on containers of various shapes and can be used to transform existing equipment without changing the container structure. Whether it is a container, hopper or reactor, adding a weighing module can turn it into a weighing system! It is especially suitable for occasions where multiple containers are installed in parallel and the space is narrow. The weighing system composed of weighing modules can set the range and scale value according to needs within the range allowed by the instrument. The weighing module is easy to repair. If the sensor is damaged, the support screw can be adjusted to lift the scale body. The sensor can be replaced without removing the weighing module.

Post time: Nov-20-2024