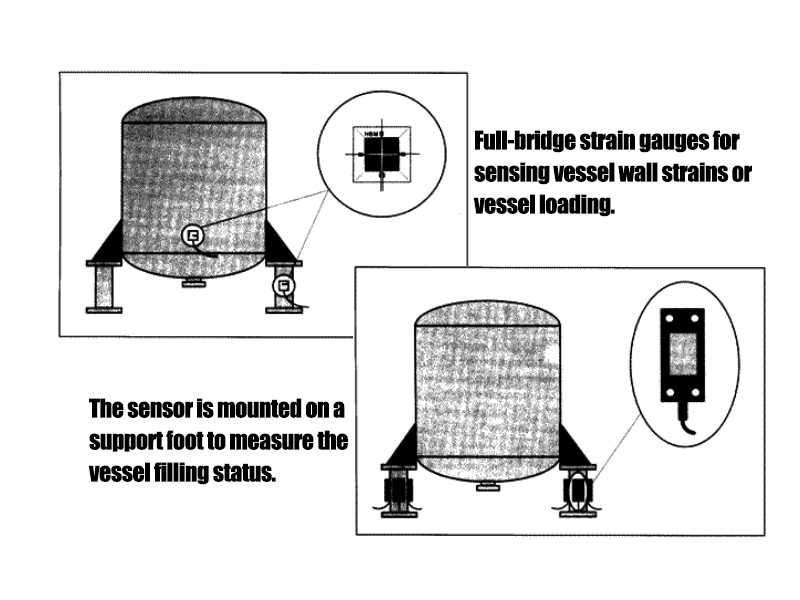

For simple weighing and inspection tasks, this can be achieved by directly affixing strain gauges using existing mechanical structural elements.

In the case of a container filled with material, for example, there is always a gravitational force acting on the walls or feet, causing deformation of the material. This strain can be measured directly with strain gauges or indirectly with pre-customized sensors to measure the state of filling or the mass of the filler.

In addition to economic considerations, this solution is particularly applicable in cases where the plant and equipment construction cannot be refurbished.

When designing new equipment, all possible additional effects on the measurement accuracy that can occur should be taken into account at the project design stage, but are sometimes very difficult to predict before the equipment is put into operation. In most cases the vessel supports are of plain steel, and temperature changes cause additional deformation of the material, which, if this effect is not compensated for to a large enough extent, can result in a measurement error. This error can only be mathematically compensated for to a limited extent in subsequent circuits.

Compensation of errors arising from temperature effects, or different load conditions (e.g. asymmetric distribution of the goods in the container), can only be realized if there are sensors on each support leg of the container (e.g. four measuring points at 90°). The economics of this option often forces the designer to reconsider. Vessel members are generally dimensionally rich to minimize member deformation, so the signal-to-noise ratio of the sensors is often less favorable. Additionally, the vessel members are generally oversized to reduce member deformation, so that the signal-to-noise ratio of the sensor is often less favorable. In addition, the nature of the material of the vessel components has a direct impact on the accuracy of the measurement (creep, hysteresis, etc.).

The long-term stability of the measuring equipment and its resistance to environmental influences must also be considered at the design stage. Calibration and recalibration of the weighing equipment is also an important part of the design phase. For example, if a transducer on just one support leg is reinstalled due to damage, the entire system must be recalibrated.

Experience has shown that a judicious selection of measuring points and a combination of scale technology (e.g. possible periodic tare) can improve accuracy by 3 to 10 percent.

Post time: Dec-22-2023