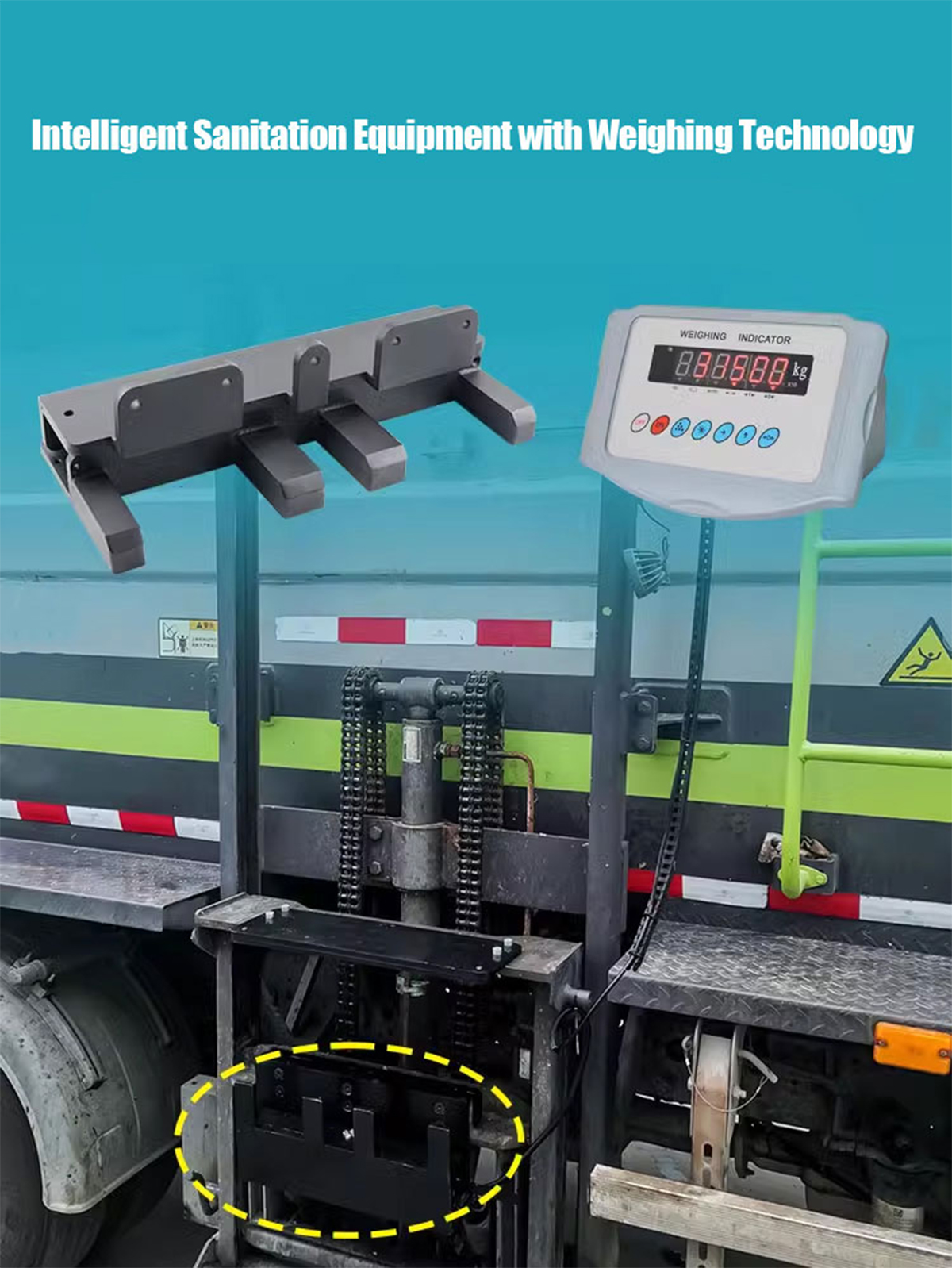

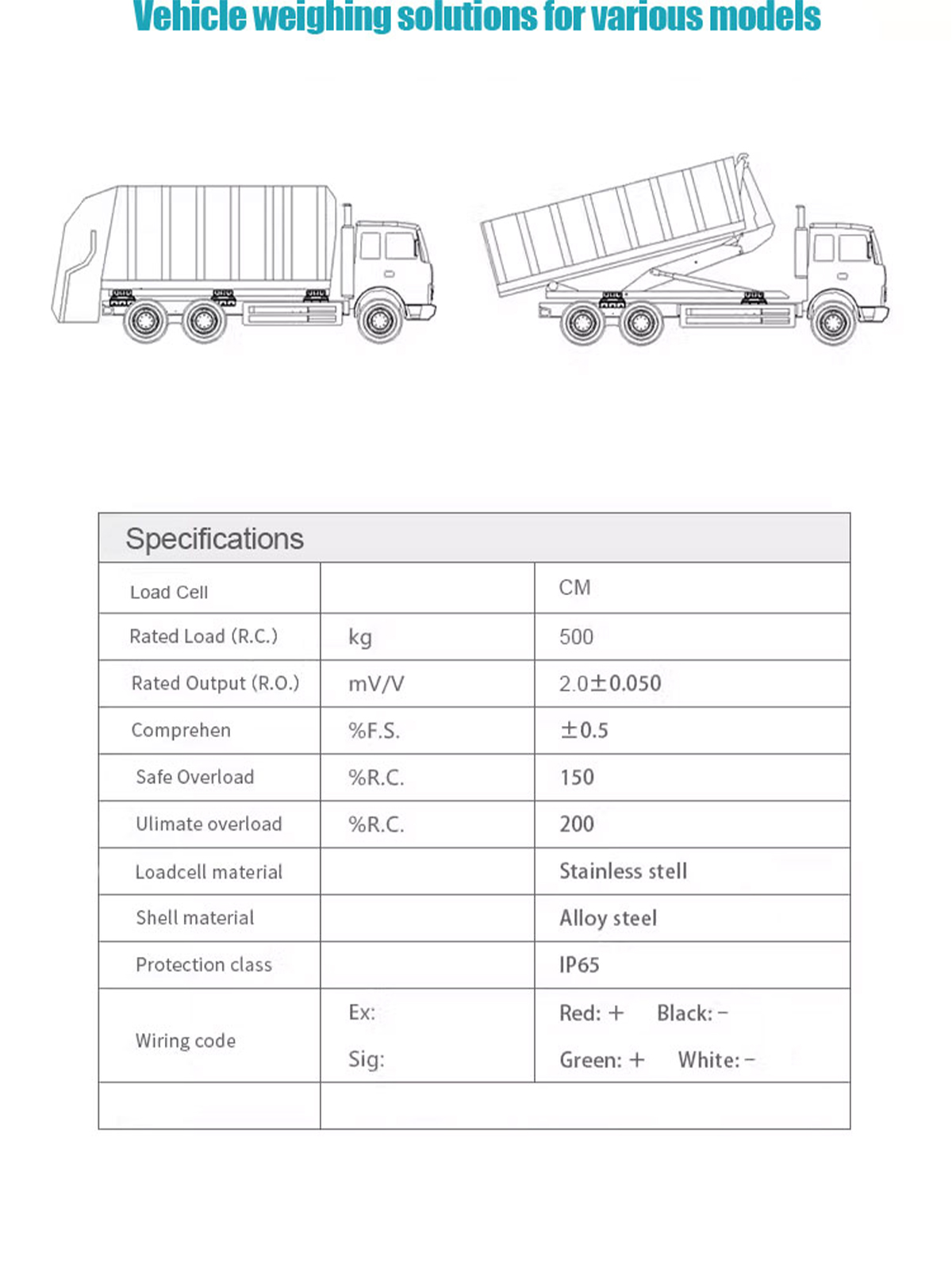

LVS Load Cell Onboard Vehicles Weighing System Vehicles Dynamic Weighing Solutions

Descriptions

While lifting bins and minimizing volume are important, waste collection vehicles face many challenges in dealing with recycling incentives and landfill penalties. As the leading supplier of onboard systems to the waste market, Labirinth Onboard Weighing offers solutions to optimize the efficiency and accuracy of loading different materials. Their range of dynamic weighing, real-time credit checking, load optimization and overload protection systems support operators in meeting these demands.

In the waste collection industry, achieving accuracy is critical to increasing profitability. Whether it is a side loader, front loader or rear loader, weighing solutions must meet benchmark standards of accuracy. This ensures that operators can increase their load capacity while remaining within legal limits and ensures accurate and timely billing for the various materials collected.

Different waste collection needs require weighing systems with different levels of accuracy. The basic level involves overload protection, ensuring compliance with legal weight limits and avoiding penalties. Load cell-based systems provide accuracy across the entire payload, which helps optimize route management and increase efficiency. It is worth noting that the accuracy of the weighing system is directly related to the payload capacity, which can vary by several tons. For the highest level of accuracy, legal-to-trade certification, air billing services and telematics can add even more value when creating flexible pay-by-weight services. Labirinth Onboard Weighing has the necessary expertise and solutions to meet your scrap fleet weighing needs, whatever the level of accuracy required.