LSC Powder Granule Loss-In-Weight Scale Feeder

Features

1. Independent research and development of W-DSP technology, higher feeding accuracy and stability, can achieve high-precision online micro-feeding.

2. The feeding part adopts stainless steel twin-screw, the screw does not stick to the material, has the function of self-cleaning, easy to disassemble, easy to clean, replace and maintain.

3. Horizontal agitation plus optional vertical agitation with optimized design has high anti-bridging performance.

4. Different models adopt a universal screw interface, which can easily replace different types of screws, and realize a wider feeding range of one equipment.

5. The speed fluctuation of the feeding motor is ±0.2%, the instantaneous flow accuracy of the material is ±0.2%, and the cumulative total is ±0.2%.

The feeding motors of the whole series are equipped with DS servo motors with higher resolution and planetary reducers as standard.

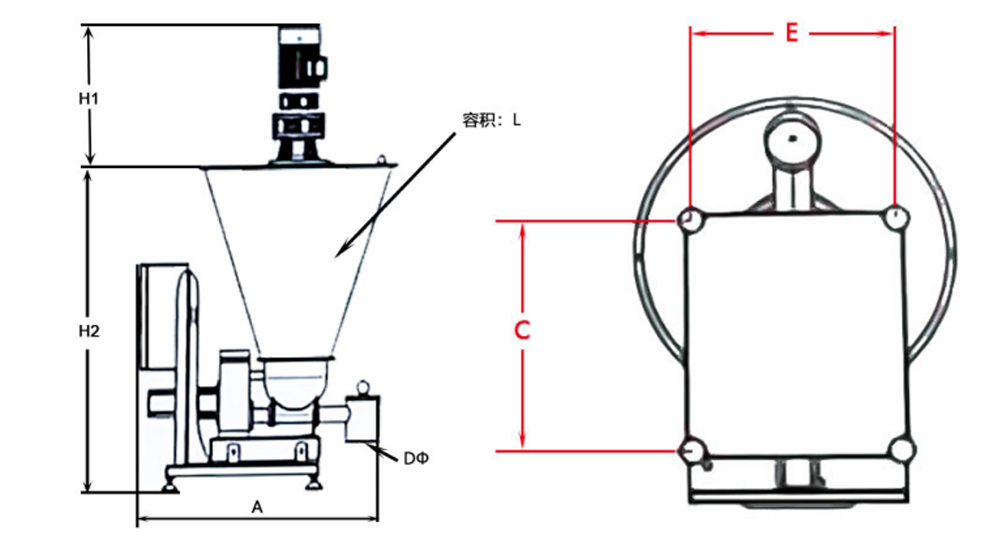

Specifications

|

Specification |

Measure range L/H |

A (mm) |

B (mm) |

C (mm) |

DФ |

EФ |

H1 (mm) |

H2 (mm) |

L(1) |

Accuracy% |

|

LSC-18 |

1-50 2-100 |

680 |

348 |

348 |

76 |

430 |

394 |

900 |

20/60 |

≤0.2 |

|

LSC-28 |

5-2000 10-400 |

780 |

404 |

464 |

108 |

630 |

394 |

930 |

80 |

≤0.2 |

|

LSC-38 |

10-500 20-1000 |

840 |

424 |

574 |

108 |

630 |

394 |

980 |

100 |

≤0.2 |

Dimensions