LC8020 High Precision Electronic Balance Counting Scale Weighing Sensor

Features

1. Capacities (kg): 5-20

2. High comprehensive precision, high stability

3. Compact structure, easy to install

4. Small size with low profile

5. Anodized Aluminum Alloy

6. The four deviations has been adjusted

7. Recommended Platform size: 200mm*200mm

Video

Applications

1. Electronic balances

2. Packaging Scales

3. Counting scales

4. Industries of food , medicine and other industrial weighing and production process weighing

Description

The LC8020 load cell is designed for electronic scales and platform scales that require a single sensor. It is very suitable for mass production operations of customers. The measuring range is from 5kg to 20kg. High precision, surface anodized treatment, protection level is IP66, can be applied in a variety of complex environments. The recommended table size is 200mm*200mm, suitable for electronic balances, counting scales, packaging scales, food, medicine and other industrial weighing and production process weighing.

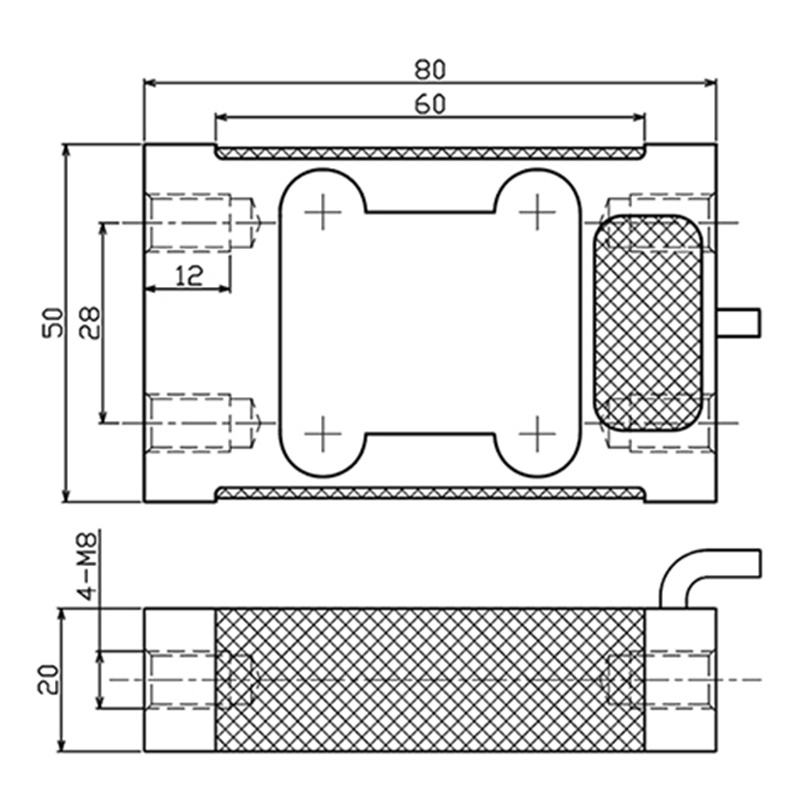

Dimensions

Parameters

| Product specifications | ||

| Specification | Value | Unit |

| Rated load | 4,5,8,10,20 | kg |

| Rated output | 1.8 | mV/V |

| Zero balance | ±1 | %R.O. |

| Comprehensive Error | ±0.02 | %R.O. |

| Zero output | ≤±5 | %R.O. |

| Repeatability | ≤±0.01 | %R.O. |

| Creep (30 minutes) | ≤±0.02 | %R.O. |

| Normal operating temperature range | -10~+40 | ℃ |

|

Allowable operating temperature range |

-20~+70 | ℃ |

|

Effect of temperature on sensitivity |

±0.02 | %R.O./10℃ |

| Effect of temperature on zero point | ±0.02 | %R.O./10℃ |

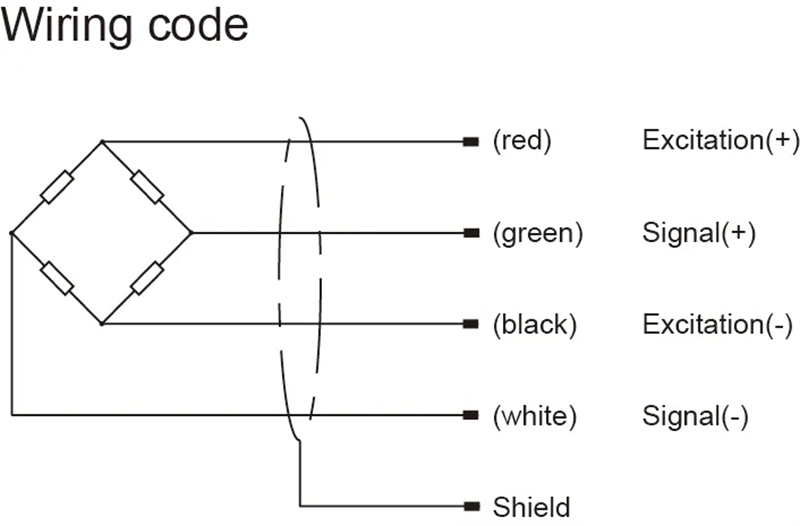

| Recommended excitation voltage | 5-12 | VDC |

| Input impedance | 410±10 | Ω |

| Output impedance | 350±5 | Ω |

| Insulation Resistance | ≥3000(50VDC) | MΩ |

| Safe overload | 150 | %R.C. |

| limited overload | 200 | %R.C. |

| Material | Aluminum | |

| Protection Class | IP65 | |

| Cable length | 2 | m |

| Platform size | 200*200 | mm |

| Tightening torque | 10 | N•m |

Tips

In belt scales, single point load cells are utilized to accurately measure the weight of materials being transported on a conveyor belt. These load cells play a crucial role in maintaining efficiency and productivity in industries such as mining, manufacturing, and logistics.The single point load cell is integrated into the belt scale system, typically mounted underneath the conveyor belt at a single point or multiple points, depending on the scale's design and requirements. As the material passes over the scale, the load cell measures the force or pressure exerted by the material on the belt.The load cell then converts this force into an electrical signal, which is processed by the scale's controller or indicator. The controller calculates the weight of the material based on the signal received from the load cell, providing accurate and real-time weight information.The application of single point load cells in belt scales offers several advantages.

Firstly, they provide accurate weight measurements, ensuring precise monitoring and control of material flow. This is essential for inventory management, production efficiency, and quality control processes.Secondly, single point load cells offer high durability and reliability. They are designed to withstand the harsh and demanding environments commonly found in industries like mining and manufacturing. With their robust construction, these load cells can resist mechanical shocks, vibrations, and temperature variations, ensuring long-term performance and minimal downtime.

Additionally, single point load cells in belt scales contribute to operational efficiency. By accurately measuring the weight of materials, these load cells enable effective monitoring of production rates, material usage, and overall process optimization. This allows companies to identify any inefficiencies, reduce waste, and improve the overall performance of their operations.Furthermore, single point load cells can be easily integrated or retrofitted into existing belt scales, providing a cost-effective solution for upgrading or replacing outdated weighing systems. Their compact and versatile design allows for easy installation and maintenance, saving time and resources.

In summary, single point load cells are essential components in belt scales, providing accurate weight measurements of materials on a conveyor belt. Their application in belt scales ensures efficient production processes, precise inventory management, and overall improved operational performance in industries such as mining, manufacturing, and logistics.