Tank weighing system

| Scope of application: | Constitutive scheme: |

| ■ Chemical industry reactor weighing system | ■ Weighing module (Weighing sensor) |

| ■ Food industry reaction kettle weighing system | ■ Junction box |

| ■ Feed industry ingredients weighing system | ■ Weighing display (weighing transmitter) |

| ■ Ingredients weighing system for glass industry | |

| ■ Oil industry mixing weighing system | |

| ■ Tower, hopper, tank, trough tank, vertical tank |

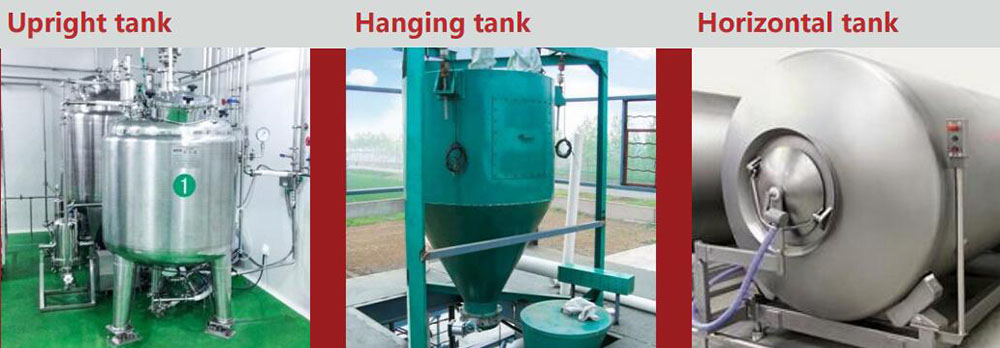

According to the load size, shape and site conditions of the container, the installation method is mainly divided into two categories:

① Pressure weighing module: Storage tanks or other structures are installed above the weighing module.

② Pull weighing module: Storage tanks or other structures are suspended below the weighing module.

According to the load size, shape and site conditions of the container, the installation method is mainly divided into two categories:

① Pressure weighing module: Storage tanks or other structures are installed above the weighing module.

② Pull weighing module: Storage tanks or other structures are suspended below the weighing module.

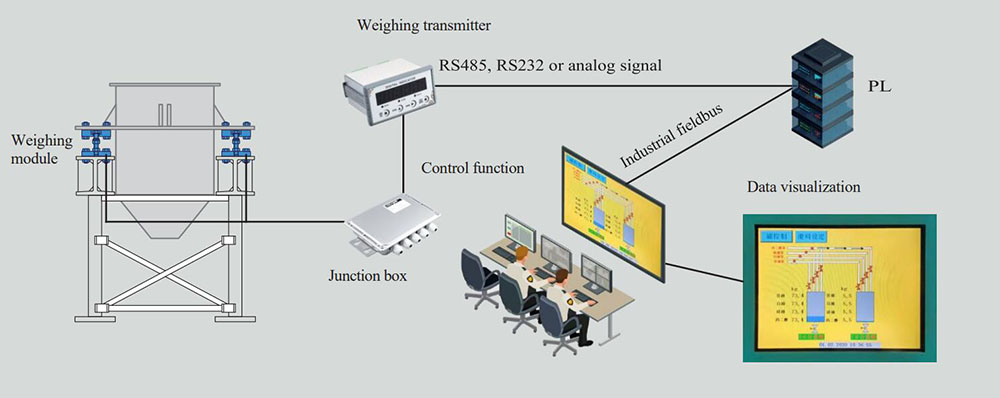

Working principle:

| Selection scheme: |

| ■ Environmental factors: Stainless steel weighing module is selected for humid or corrosive environment, explosion-proof sensor is selected for flammable and explosive occasions. |

| ■ Quantity selection: According to the number of support points to determine the number of weighing modules. |

| ■ Range selection: fixed load (weighing table, batching tank, etc.) + variable load (load to be weighed) ≤ selected sensor rated load × number of sensors × 70%, of which 70% factor is considered vibration, shock, off-load factors and added. |

| ■ Capacity:5kg-5t | ■ Capacity:0.5t-5t | ■ Capacity:10t-5t | ■ Capacity:10-50kg | ■ Capacity:10t-30t |

| ■ Accuracy:±0.1% | ■ Accuracy:±0.1% | ■ Accuracy:±0.2% | ■ Accuracy:±0.1% | ■ Accuracy:±0.1% |

| ■ Material:alloy steel | ■ Material:alloy steel/stainless steel | ■ Material:alloy steel/stainless steel | ■ Material:alloy steel | ■ Material:alloy steel/stainless steel |

| ■ Protection:IP65 | ■ Protection:IP65/IP68 | ■ Protection:IP65/IP68 | ■ Protection:IP68 | ■ Protection:IP65/IP68 |

| ■ Rated output:2.0mv/v | ■ Rated output:2.0mv/v | ■ Rated output:2.0mv/v | ■ Rated output:2.0mv/v | ■ Rated output:2.0mv/v |