901 Multi-Specification Dynamic And Static Torque Meter Torque Sensor

Features

1. Capacities (Nm): ±5……±500000

2. Using a unique non-contact transmission method to input and output signals

3. Can measure dynamic torque and static torque

4. Working principle: wireless power supply and wireless output

5. There is no need to adjust the zero point when measuring forward and reverse torques

6. The signal adopts digital technology, strong anti-interference

7. Input power polarity, output torque, speed signal protection

8. There are no wear parts such as collector rings, and it can run at high speed for a long time

9. Torque measurement accuracy has nothing to do with rotation speed and direction

10. High precision and good stability

11. Can measure forward and reverse torque, speed and power

12. Small size, light weight, easy installation

13. High reliability and long life

14. Can be installed in any position and direction

Product Description

901 torque sensor dynamic torque sensor and static torque sensor. 5N·m to 500000N·m multi-spec dynamic and static torque sensor torque meter.

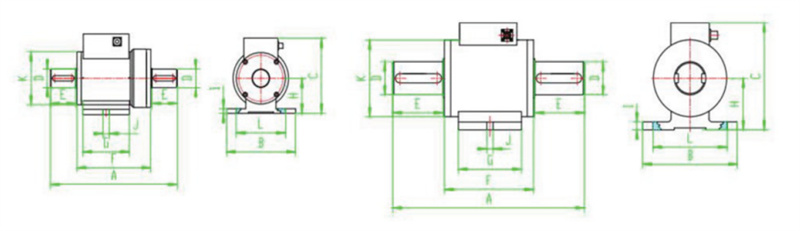

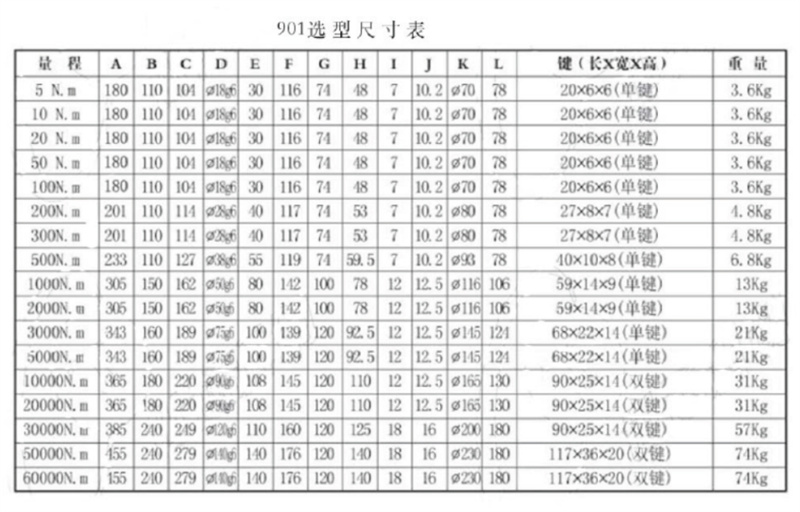

Dimensions

Parameters

| Measuring range | 0-±5. ±10. ±20. ±50. ±100. ±200. ±500. ±1000±2000. ±5000. ±10000.±20000. ±30000. ±50000. ±60000. ±80000. ±100000. ±150000. ±200000±300000. ±500000 |

| output signal | 5-15KHz,1-5v,0-10v,O-±5v,4-20mA |

| amplitude | 10v |

| power | 4w |

| Working speed | 0-30000r/min(any rotate speed optional) |

| supply voltage | 24VDC ±15VDC optional |

| response frequency | 100μS |

| ambient temperature | -60-70℃ |

| maximum load | 150%FS |

| insulation resistance | >200 MΩ |

| zero drift | <0.5% |

| precision | 0.1% 0.25% 0.5% optional |

| repeatability | <0.1 |

| linearity | <0.1% |

| Hysteresis | <0.1% |

| Relative humidity | <90%RH |

| Dynamic strain wave response time | 32X10-6S |

Precautions

1. The wiring of this series of torque sensors must be connected according to the wiring diagram, and the power can only be turned on after confirmation.

2. Check that the selected power supply must be consistent with the input power supply of the sensor.

3. The output of the signal line cannot be connected to the ground, which will cause a short circuit.

4. The shielding layer of the shielded cable must be connected to the common terminal power supply of +1 5V power supply.

5. When the sensor is fixed, it must be firmly fixed with the equipment base. The center height must be properly adjusted to avoid bending moments. The center height error should be less than 0.05mm.

6. If you have any questions during use, please contact our company in time, and you are not allowed to disassemble it by yourself during the warranty period.

7. Never insert or remove the plug when the power is on.

8. Output signal: Square wave frequency ±15KHz Zero point: 10 KHz, forward full scale: 15KHz, reverse full scale 5KHz Output 4-20mA: Zero torque: 12.000 mA; Forward full scale: 20.000mA; Reverse full scale: 4.000 mA

9. This series of torque sensors can work for a long time due to the induction power supply, and are widely used in torque monitoring of motors, centrifuges, generators, reducers, and diesel engines.

10. If you need to measure the speed, just install a special speed measuring device on the shell of this series of torque sensors. The sensor and its tachometer wheel can measure the speed signal of 6-60 square waves per revolution.

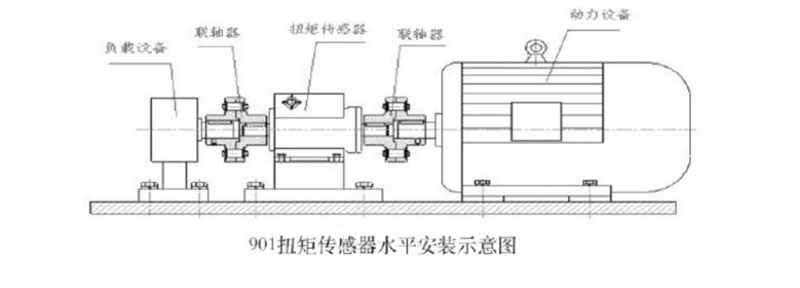

11. Using two sets of couplings, install the belt torque sensor between the power source and the load.

12. Power and load equipment must be fixed and reliable to avoid vibration.

13. Fix the base of the torque sensor and the base of the equipment as flexibly as possible (can swing) to avoid bending moment.

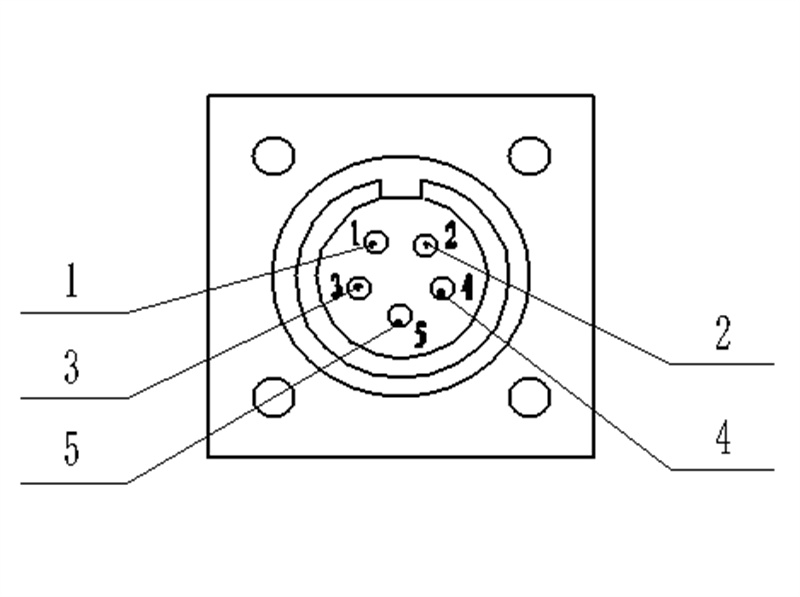

Wiring

1. Grounding

2. +15v

3. -15v

4. Speed signal output

5. Torque signal output